Using a Direct-to-Substrate UV Printer for Short-Run Package Printing

Fast, new industrial-grade UV printers do much more than package prototyping and proofing. You can also use them to print short runs of customized packaging.

Do you need to print labels, folding cartons, rigid boxes, paper bags or plastic sheets? What about film sleeves, corrugated display and shipping boxes?

UV printer can handle the job. We designed our UV printers for extreme versatility regardless of what you print on. You can print rigid and flexible materials and even bottles.

That’s unlike others devices which can’t produce unattended short-run production.

With Compress, it doesn’t matter if your packages are in batches ranging from one to one thousand or more. And, each package in the run can have a different barcode, language, or image.

Who Can Benefit

Print-service providers and package printing

Use direct-to-substrate UV printers to provide small quantities of custom packaging. You can use them for local businesses, boutiques, farms, pizza shops, & other restaurants.

Also, art galleries, photography studios, and start-up companies. Marketing agencies need small batches of package printing for product launches and presentations.

Use UV Printers for E-tailers

Print-service providers can produce custom packaging on demand. Regardless if they are produce orders as they come in or online.

Traditional manufacturers

Use short runs of packaging for test marketing, advertising, and photo shoots.

You can do launch events, or shipments to sites where English is not the primary language.

Brand marketers

Use shorter runs of packaging for “limited-edition” products that will be sold only in a limited area and for a short period of time.

Why Custom Packaging Matters

Marketing executives know that well-designed packaging can be a critical for branding.

How you package a product affects the perceived value of the product. Your package printing needs to look unique on store shelves to get noticed.

The ability to produce short runs of customized packaging has become more cost-effective. Practical even for small, local businesses to have custom packaging designed and printed.

Often the packaging box represents the buyer’s first touchpoint with a retail brand. Does the package printing look cheap? Is it interesting and create a favorable impression?

When you open up a well-designed package it can feel like opening a gift.

There are also cost benefits of producing short runs of packaging. You can save costs by stocking fewer items. Furthermore, you don’t have to carry hundreds or thousands of items in all the different sizes. And, you can print your packages with seasonal messages or images throughout the year.

Not only that, but printed QR codes lead buyers to your website. You can make fresh promotional offers or give updated information.

You also save money because you won’t have tons of obsolete packaging boxes lying around. When they become obsolete, you may as well pitch them.

Printing your own custom graphics reduces the time and expense to print or apply the labels.

Brand marketers and designers understand the profitability of short runs of custom-designed packaging

Innovative ideas are cropping up every day. For example, some marketers now offer personalized packaging to customers. They do this as an incentive for engaging with the brand online or in social media.

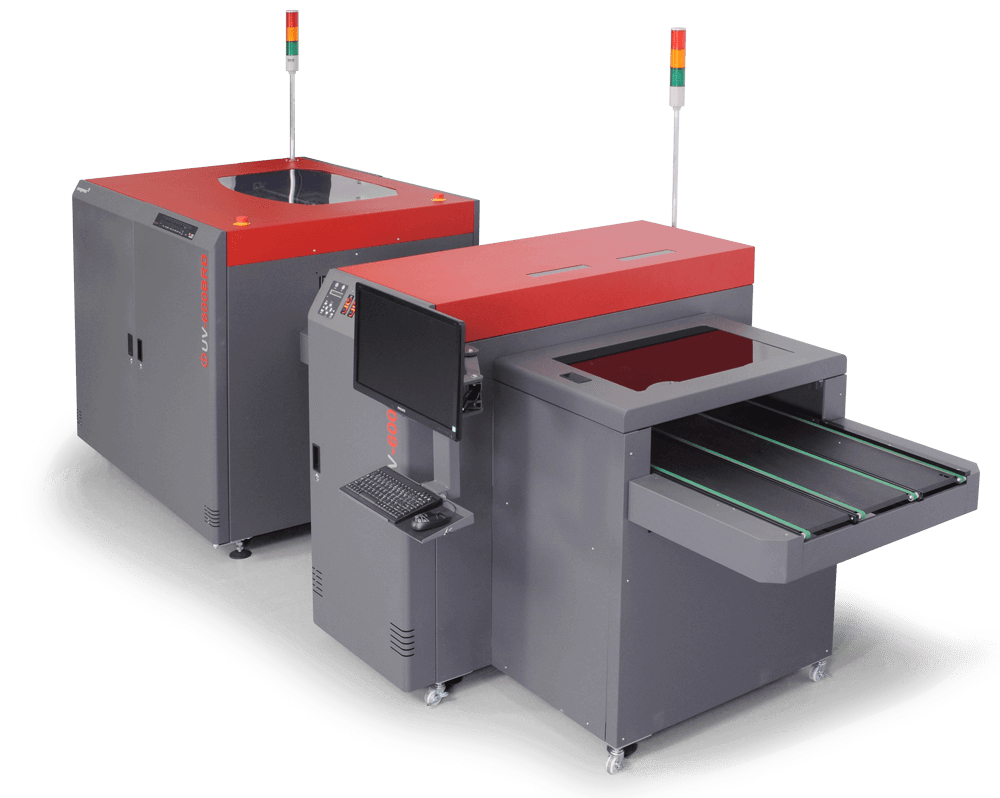

Industrial UV Printers for Short Run Packaging

With a fast, industrial UV printer from Compressuvprinter.com, you can help creative designers experiment with short-run packaging.

The Compress® iUV-600 BRD Series can print customized packaging all day with minimal operator intervention. As board stocks, plastic sheets, of corrugated materials feed continuously from the auto-cartridge loader through the printer and onto an automated sheet loader, thousands of sheets up 23.6 inches (600 mm) wide x 47.2 inches (1200 mm) long can be individually customized with variable data, barcodes, or copy changes. Materials up to 78.7 inches (2000 mm) long can be fed manually.

The Compress® iUV-600s/1200s printers give you the speed and versatility to print package designs on everything from rolls of paper, films, and light cardboard to sheets of metal, acrylic, and board stocks. You can also decorate rigid boxes up to 11.8 inches deep. With the optional bottle jig, you can print directly on glass and plastic bottles.

Two energy-efficient, precision-controlled UV-LED lamps instantly cure the UV-light-sensitive inks on the packaging materials as they pass quickly through the printer onto the automated sheet loader. The lights remain cool enough not to distort films, plastics, or other heat-sensitive packaging materials.

Use the optional white ink to print images and bright colors on clear substrates. Use the optional clear ink to give packaging materials a distinctive texture or embossed-like feel. Textured backgrounds or raised logos and lettering add to the perceived quality of the packaged item.

The iUV 600s printer has a print bed of 24 in. x 17.7 inches (604 mm x 450 mm). The iUV 1200s has a print bed of 45.2 inches x 29.5 inches (1150 mm x 750 mm). On both printers, the printhead can be raised to 11.8 inches high.